Burner filters

Gas filters are usually installed at the entrance to the control and measuring station and are used to filter gases. They serve to stop and collect impurities (solid particles, dust, rust and condensate from the gas stream) up to 5 (m. You can download the technical documentation in pdf format.

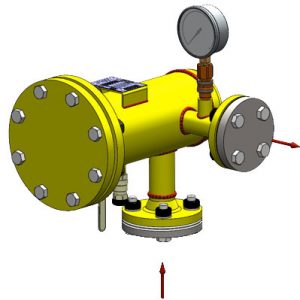

After the gas enters the gas filter, due to the change in the direction of flow and the speed of the gas, larger impurities are separated and collected at the bottom of the filter. The gas passes through the filter cartridge, where the remaining impurities up to 5 µm are separated. According to special requirements, we make filters with electrical bypass to equalize the electrical potentials between the cover and the housing (copper cable with feet of appropriate diameter or serrated washers).

The gas filter, together with other equipment, is installed in the control and measuring stations, and during installation it is necessary to observe:

- the direction of gas flow through the filter (see direction of the arrow on the filter),

- the height of the axis of the gas inlet-outlet connection,

- inspect the filter to ensure that no damage has occurred during transport.