CNG Gas Stations

We are proud partners of leading world companies that work with CNG systems.

AREAS OF CNG USE

- Asphalt factories

- Chemical industry

- Building materials industry

- Metallurgical industry

- The food industry

- Mining

- Other industrial plants

Services we offer asphalt plants

- Analysis of natural gas use: daily, monthly, annually

- Separate natural gas meters for the dryer and bitumen heating line

- Remote meter reading

- Remote pressure reading on the pallet

- Burner consumption control separately

- Establishment of a natural gas system within 4 days

- Space for a CNG tank that can be changed in half a day, depending on the condition of the construction site

Advantages of CNG in asphalt plants

| CNG is highly efficient | Difference in operational efficiency up to 9% in peak draft For example, the rate of evaporation of liquefied fuels at peak draft (over 1,000 Sm3 / h) may not be sufficient, the system may have low gas pressure and thus reduce production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| No additional costs | There are no costs for insulation and maintenance of pipelines as with fuel oil systems. |

| Alternative system | If desired, the LNG system can be installed next to the CNG system, and Naturelgaz can install a system that automatically changes the power source. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

| Mobile system | The location of the CNG installation can change in about half a day; It is possible to change the installation site without interruption between jobs when changes need to be made due to the course of work or land use. In LNG, this process will take at least a week, and the LNG in the tank will be depleted and some will be consumed. |

Services we offer to the chemical industry

- Analysis of natural gas use: daily, monthly, annually

- Automatic shipment management system

- Remote meter reading

- Remote pressure reading on the pallet

- Establishment of a natural gas system within 4 days

- CNG supply with specially trained staff

- Supplementing with a special export regime within the Free Zone

Advantages of CNG in the chemical industry

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | For example, with peak drafts (over 1,000 Sm3 / hour) drafts, the rate of evaporation of liquefied fuels may not be sufficient, there may be low gas pressure in the system, and thus a reduction in production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| No additional costs | There are no costs for insulation and maintenance of pipelines as with fuel oil systems. |

| Alternative system | If desired, the LNG system can be installed next to the CNG system, and Naturelgaz can install a system that automatically changes the power source. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

Services we offer to their companies

- Analysis of natural gas use: daily, monthly, annually

- Automatic shipment management system

- Providing data for energy saving programs

- Remote meter and pallet reading

- Flexible accounting periods

- CNG supply with specially trained staff

Services we offer to their companies

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | Especially at peak drafts (over 1,000 Sm3 / hour), the evaporation rate of gasified fuels may not be sufficient, and there may be low gas pressure in the system, thus reducing plant production capacity. The experience of our great customers; This means that when they use CNG they can reach full capacity in a plant with a capacity of 240 tons / hour, but the production of some plants with other fuels can drop to 200 tons / hour. (240/220 = 9%) |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

Services we offer to their companies

- Analysis of natural gas use: daily, monthly, annually

- Automatic shipment management system

- Remote meter and pallet reading

- Preparation of explosion protection document

- Report a special price in case of termination of the purchase request

- Possibility of supplementing with large pallets

Services we offer to their companies

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | For example, with peak drafts (over 1,000 Sm3 / hour) drafts, the rate of evaporation of liquefied fuels may not be sufficient, there may be low gas pressure in the system, and thus a reduction in production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

Services we offer to their companies

- Analysis of natural gas use: daily, monthly, annually

- Automatic shipment management system

- Providing data for energy saving programs

- Remote meter and pallet reading

- Stainless steel pressure relief center

- Data transfer to automation systems with web service

- Special CNG design of the site for environmental protection

Services we offer to their companies

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | For example, with peak drafts (over 1,000 Sm3 / hour) drafts, the rate of evaporation of liquefied fuels may not be sufficient, there may be low gas pressure in the system, and thus a reduction in production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

Services we offer to their companies

- Analysis of natural gas use: daily, monthly, annually

- Automatic shipment management system

- Providing data for energy saving programs

- Remote meter and pallet reading

- Ability to combine information from different objects

- Data transfer to process monitoring systems with web service

Services we offer to their companies

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | For example, with peak drafts (over 1,000 Sm3 / hour) drafts, the rate of evaporation of liquefied fuels may not be sufficient, there may be low gas pressure in the system, and thus a reduction in production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

Services we offer to their companies

- Analysis of natural gas use: daily, monthly, annually

- Report a special price in case of termination of the purchase request

- Possibility of replenishing stocks with stocks that can be changed periodically

- HSSE training and preparation of explosion protection documents

Services we offer to their companies

| Difference of operational efficiency up to 9% in top drawings | |

| CNG is highly efficient | For example, with peak drafts (over 1,000 Sm3 / hour) drafts, the rate of evaporation of liquefied fuels may not be sufficient, there may be low gas pressure in the system, and thus a reduction in production capacity. The experience of our great customers; That is, they can save 9% when using CNG. |

| No storage costs | It is invoiced with a CNG meter, it is paid as much as it is used. |

| Natural gas installation | The first phase pressure reduction centers and the second phase pressure reduction centers used for CNG are built with the approval of an advisor approved by EMRA. |

CNG characteristics

| Physico-chemical properties of CNG | Unit |

|---|---|

| Molecular weight | 16.4 gr / mol |

| Boiling point | -162 ° C |

| Freezing point | -182 ° C |

| Freezing point | -188 ° C |

| Latent heat of vaporization | 504 kJ / kg |

| Critical temperature | -82.5 ° C |

| Critical pressure | 42.95 bar |

| Self-ignition point | 537 ° C |

| Explosion limit | 5-15% |

| Gas density | 0.66 kg / Sm 3 |

| Specific weight | 0.55 (Air = 1) |

| Composition of CNG | % |

|---|---|

| Methane (CH 4 ) | 70 – 90 |

| Ethan (C 2 H 6 | 5 – 15 |

| Propane (C 3 H 8 ) and Bhutan (C 4 H 10 ) | 5 |

| CO 2 , N 2, H 2S, etc. | the rest |

CNG characteristics

CNG is a highly efficient fuel

CNG has no storage costs

The CNG system is mobile

CuboGas

When choosing a system with natural GAS, experience counts!

CUBOGAS offers integrated “plug & fill” solutions complete with all the accessories necessary for the installation of a compressor and a petrol station. CUBOGAS systems are efficient in all inlet pressure conditions (0.1 to 100 barg / 1.45 to 1,450 psi) and are ideal for all petrol station needs thanks to their flexibility.

Product information

The dew point of natural gas at the outlet of the dispensary must be below the lowest ambient temperature in which the dispensary will operate.

It should be noted that the compression effects will increase the dew point of the gas: although the dew point of the gas in a particular pipeline is very low when it reaches the compressor, it will be significantly higher when the gas leaves the compressor.

Safety comes first

Safety is the key to everything, so all our units comply with the strictest international safety standards and are fully tested before delivery. Compact design, low noise and no vibration make CUBOGAS particularly suitable for urban areas. CUBOGAS also complies with all applicable environmental regulations. An effective hermetic seal, silence and a special integrated exhaust system help to ensure a very low environmental impact.

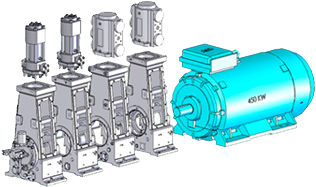

Modular technology to improve performance and reduce costs

For our CNG solutions, we use the most advanced industrial technology not only to improve their efficiency but also to reduce maintenance costs. The heart of CUBOGAS is an innovative and very efficient reciprocating compressor. Designed according to API 618 standards, it has a conservative rotation speed that ensures safer, quieter and more reliable operation. The transverse head and coolant from the aluminum cylinder increase the life of the compressor even more – CUBOGAS is actually designed to operate 24 hours a day, even in extreme conditions. Furthermore, since the cylinders are not lubricated, there is no risk of oil contamination of the tank, and you can also save on lubricant costs. For CNG applications that use small cylinders, we also offer a unique vertical compressor that not only takes up less space, but also protects vital components from unnecessary wear. And convenient access to services facilitates maintenance, reducing unit downtime.

Product information

The CNG storage is filled with a compressor that can reach up to 250 bar. It has mainly two functions:

- for compressing gas storage to optimize compressor start-up and shutdown and faster vehicle charging immediately

- dampen the vibrations emanating from the compressor, preventing these vibrations from reaching the tapping column

Product information

Responding to the growing demand for environmentally friendly alternative fuels is now easier with the supply of up to 5 different types of fuels from a single dispenser.

Product information

Optional accessories allow complete control of your gas station, including remote access, allowing you to better monitor and manage the station. The main control panel (MCP) will allow you to control all compressors and equipment in the same station, and the Supervisor Management System (SMS) software will allow you to fully control your station and display all information parameters about the operation of stations in real time.

Their innovative and modular technology increases efficiency and reduces operating costs.

-

Innovative reciprocating compressor designed based on API 618 standard;

-

Conservative rotation speed limits wear;

-

Designed to function 24/7 regardless of conditions;

-

Unlubricated cylinders reduce costs and risks of contamination.

Select the category you are interested in and discover the CUBOGAS solutions for each of them, the specifications of individual stations, their location and a photo gallery of installed systems.